Universal Valve Guide puller Remover & Installer set – mechanical type 33pc wood

| Manufacturer | TOKAR |

|---|

— 33 pcs;

— Anti corrosion coating;

— Wooden Packing Cases.

Kit comes:

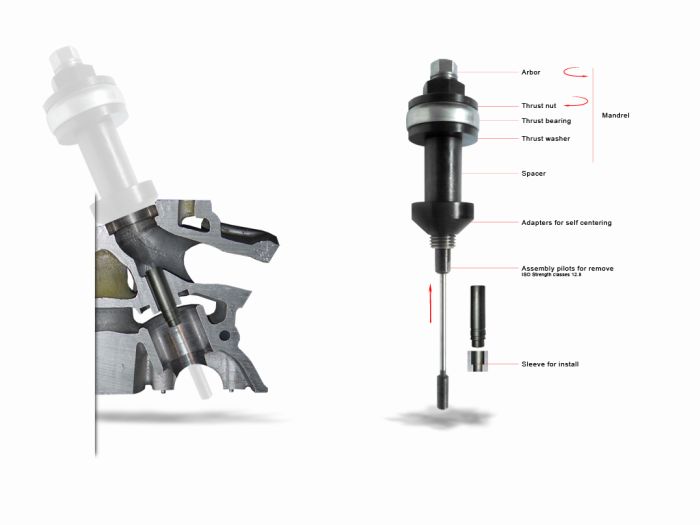

| Mandrel: | Adapters for self centering at valve seat for arbor: |

| — arbor; — thrust nut; — thrust washer; — thrust bearing. |

— Ø 25; — Ø 33; — Ø 35; — Ø 38; — Ø 40; — Ø 43; — Ø 45. |

| assembly pilots for remove and install valve guides (ISO Strength classes 12.8): |

Spacers: |

| — Ø 5; — Ø 6; — Ø 7; — Ø 8; — Ø 9; — Ø 10. |

— L= 15; — L= 30; — L= 45; — L= 50; — L= 60. |

| Sleeve for install: | |

| — Ø 5; — Ø 6; — Ø 7; — Ø 8; — Ø 9; — Ø 10. |

Replacement of Valve Guide Bushings in the Cylinder Head (CH)

When replacing old valve guide bushings, it is important to consider that the bushing may have Seizing / welded in the cylinder head bore.

Seizing / Welded of the valve guide bushing is a process where the bushing tightly "sticks" in the bore due to:

-

thermal expansion of metals,

-

lack of lubrication,

-

corrosion,

-

incorrect installation.

Force Required to Press Out the Valve Guide Bushing

| Bushing Fit Condition | Press Force (tons) | Force, kN |

|---|---|---|

| Normal fit (no seizing) | 1–2 tons | 10–20 kN |

| Light seizing | 2–5 tons | 20–50 kN |

| Heavy seizing or scoring | 5–10 tons and above | 50–100 kN and above |

In case of heavy seizing, bushing damage is possible and mechanical processing may be required.

Maximum Breaking Loads for Puller Studs (Strength Class ISO 12.9)

| Thread Size | Force, kg | Force, kN |

|---|---|---|

| M5 | 1563 kg | 15.33 kN |

| M6 | 2213 kg | 21.69 kN |

| M7 | 3181 kg | 31.24 kN |

| M8 | 4030 kg | 39.52 kN |

| M9 | 5020 kg | 49.28 kN |

| M10 | 6388 kg | 62.65 kN |

Force Developed by the Mandrel (Strength Class ISO 6.8)

| Thread Size | Force, kg | Force, kN |

|---|---|---|

| M20 | 11990 kg | 117.68 kN |

Important Recommendations

-

The mandrel develops significantly higher force than the studs.

-

Improper use of studs may cause them to break, leading to damage and additional costs.

-

To facilitate removal:

-

Heat the cylinder head with an industrial heat gun or oven to 180–250 °C.

-

Cool the bushing using an aerosol freezer, liquid nitrogen, or cold spray.

-

-

Use pin punch tool to start valve guide moving.

-

If the bushing does not come out:

-

Stop applying force; do not use excessive effort.

-

Reheat the cylinder head.

-

Try light hammer taps on the puller body to help break the bushing loose.

-

Do not increase lever arm or pressure excessively to avoid damaging the cylinder head.

-

-

If the bushing still won’t budge, proceed to alternative methods:

-

Drilling out the bushing,

-

Using a hydraulic press, etc.

-