Universal Valve Guide puller Remover & Installer set – mechanical type 16pc box

| Manufacturer | TOKAR |

|---|

— 16 pcs;

— Anti corrosion coating;

— plastic Packing box.

Puller screw for smooth removal and install valve guides, ensure safe replacement of valve guides.

Using this tool the job is done without heating the cylinder head thus giving a feedback feel that the fit is correct.

Kit comes:

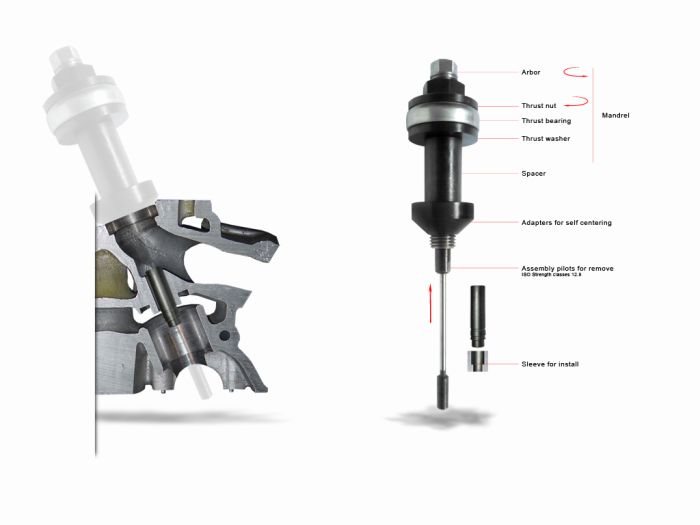

| Mandrel: | Adapters for self centering at valve seat for arbor: |

| — arbor; — thrust nut; — thrust washer; — thrust bearing. |

— Ø 33; — Ø 35; — Ø 45; |

| assembly pilots for remove and install valve guides (ISO Strength classes 12.8): |

Spacers: |

| — Ø 7; — Ø 8; — Ø 9; |

— L= 15; — L= 30; — L= 50; |

| Sleeve for install: | |

| — Ø 7; — Ø 8; — Ø 9; |

Replacement of Valve Guide Bushings in the Cylinder Head (CH)

When replacing old valve guide bushings, it is important to consider that the bushing may have Seizing / welded in the cylinder head bore.

Seizing / Welded of the valve guide bushing is a process where the bushing tightly "sticks" in the bore due to:

-

thermal expansion of metals,

-

lack of lubrication,

-

corrosion,

-

incorrect installation.

Force Required to Press Out the Valve Guide Bushing

| Bushing Fit Condition | Press Force (tons) | Force, kN |

|---|---|---|

| Normal fit (no seizing) | 1–2 tons | 10–20 kN |

| Light seizing | 2–5 tons | 20–50 kN |

| Heavy seizing or scoring | 5–10 tons and above | 50–100 kN and above |

In case of heavy seizing, bushing damage is possible and mechanical processing may be required.

Maximum Breaking Loads for Puller Studs (Strength Class ISO 12.9)

| Thread Size | Force, kg | Force, kN |

|---|---|---|

| M5 | 1563 kg | 15.33 kN |

| M6 | 2213 kg | 21.69 kN |

| M7 | 3181 kg | 31.24 kN |

| M8 | 4030 kg | 39.52 kN |

| M9 | 5020 kg | 49.28 kN |

| M10 | 6388 kg | 62.65 kN |

Force Developed by the Mandrel (Strength Class ISO 6.8)

| Thread Size | Force, kg | Force, kN |

|---|---|---|

| M20 | 11990 kg | 117.68 kN |

Important Recommendations

-

The mandrel develops significantly higher force than the studs.

-

Improper use of studs may cause them to break, leading to damage and additional costs.

-

To facilitate removal:

-

Heat the cylinder head with an industrial heat gun or oven to 180–250 °C.

-

Cool the bushing using an aerosol freezer, liquid nitrogen, or cold spray.

-

-

Use pin punch tool to start valve guide moving.

-

If the bushing does not come out:

-

Stop applying force; do not use excessive effort.

-

Reheat the cylinder head.

-

Try light hammer taps on the puller body to help break the bushing loose.

-

Do not increase lever arm or pressure excessively to avoid damaging the cylinder head.

-

-

If the bushing still won’t budge, proceed to alternative methods:

-

Drilling out the bushing,

-

Using a hydraulic press, etc.

-